The Material Economics Doctrine

Why inputs change economies faster than arguments

Why This Conversation Matters

I was recently challenged by a colleague with more than 30 years in manufacturing on whether hemp and bamboo could actually move the needle on supply chains and industrial economics.

It was a fair challenge. And it forced the right conversation. Not about sustainability slogans, but about how industrial systems actually change.

What follows is not theory. It is a doctrine grounded in how cost, risk, capital, labor, and power move when inputs change.

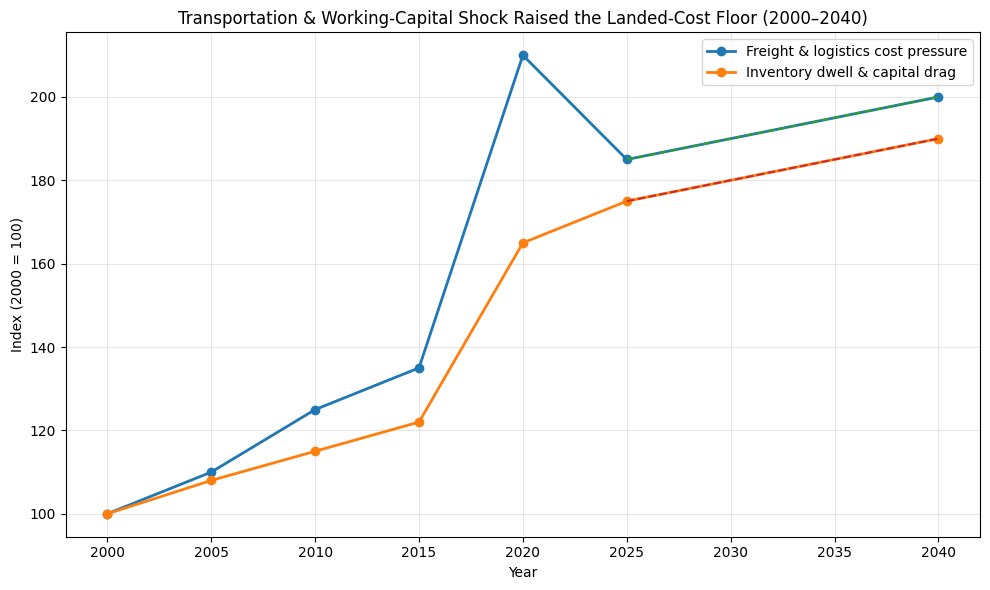

Why Now

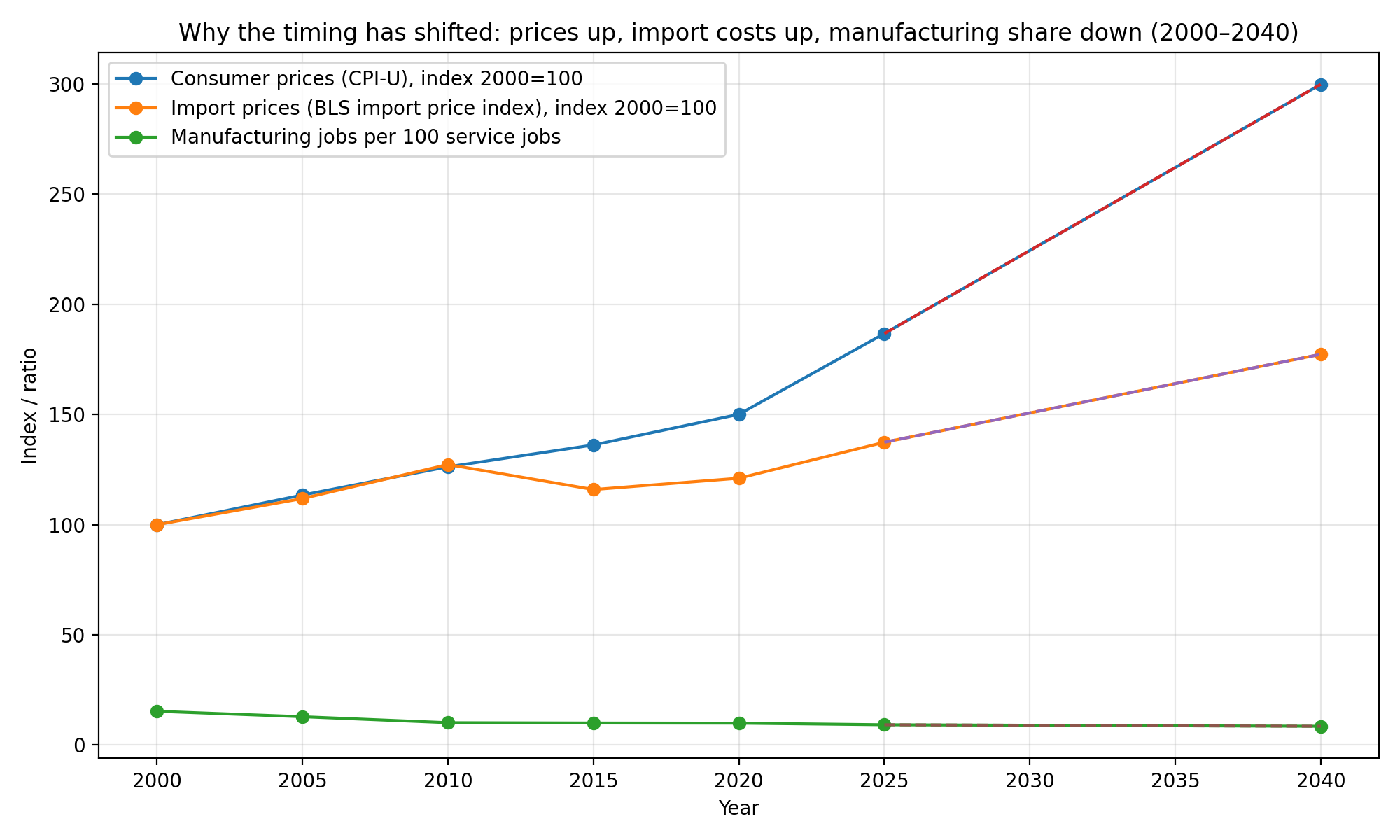

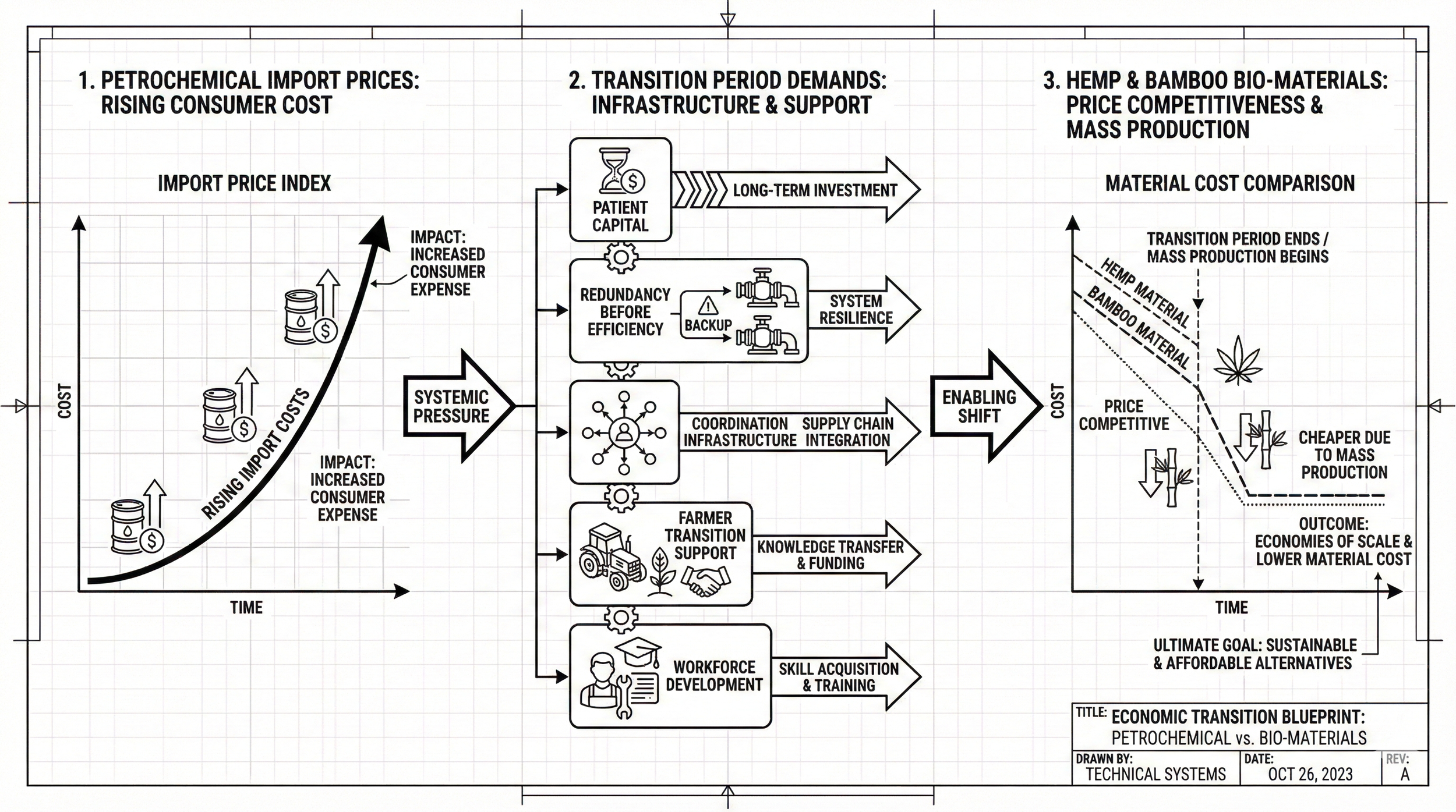

The bioeconomy is not waiting on perfection. It is already competitive in multiple lanes today because the old cost assumptions broke.

Tariffs, import compliance, freight, door to door logistics, port congestion, insurance, inventory dwell time, and working capital drag have structurally raised landed cost. At the same time, labor, energy, regulatory, and financing costs in China and Southeast Asia have risen materially.

The question is no longer whether domestic bio based inputs can compete. In many categories, they already do once risk and capital costs are fully counted. What remains is scale, standards, and execution.

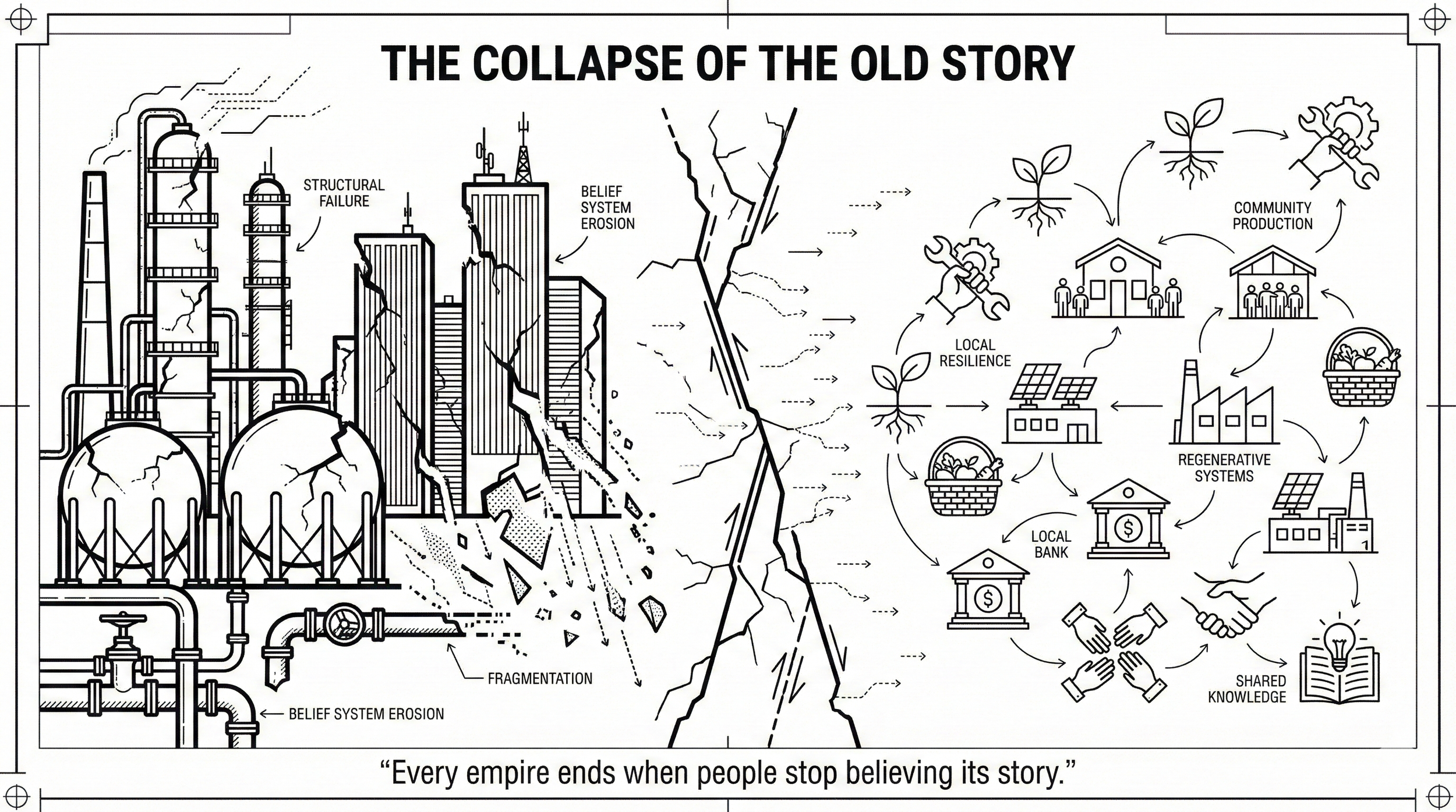

Economies Change by Inputs, Not Protest

Protests do not drive systemic change. Inputs do.

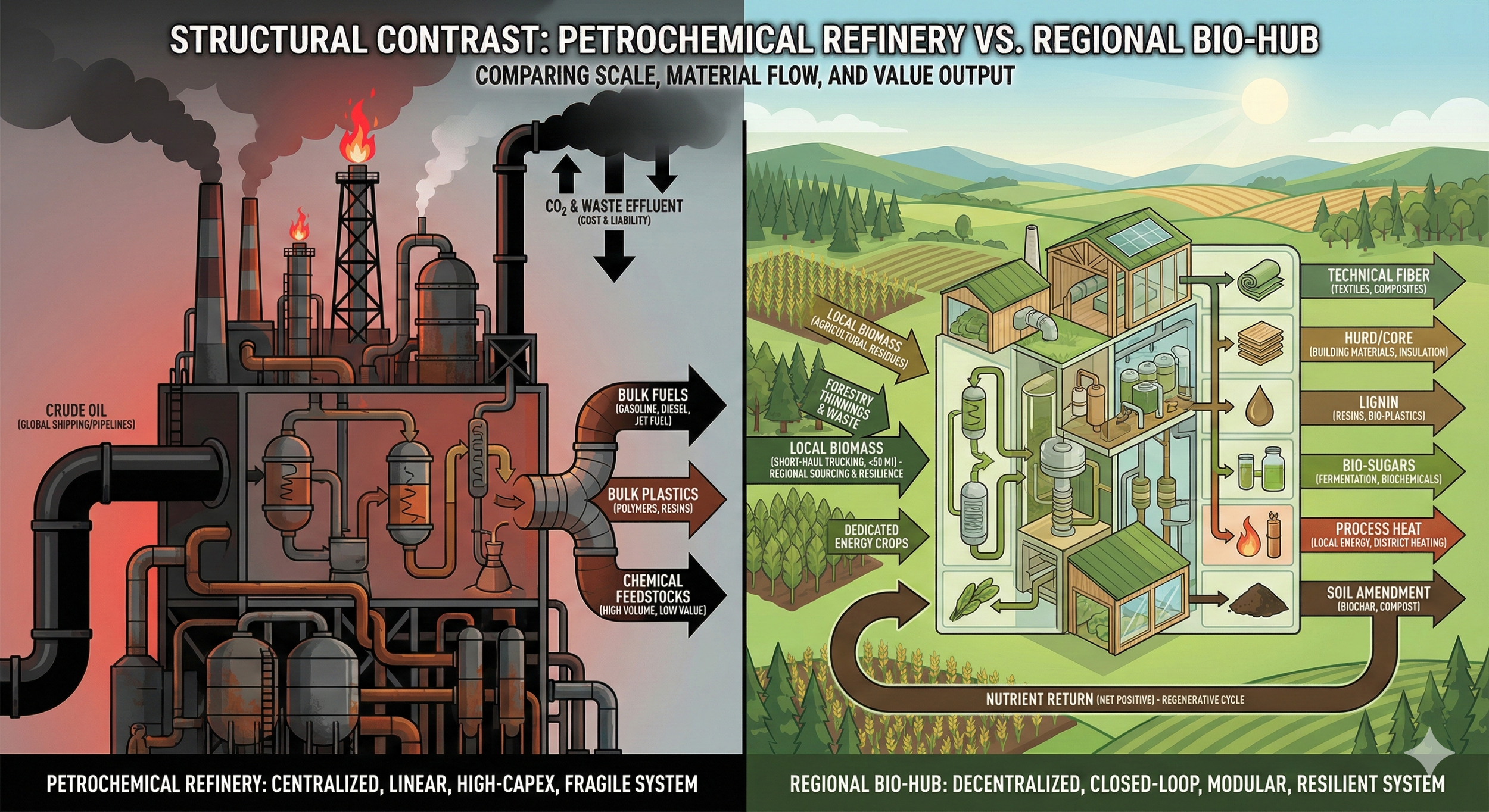

Materials determine cost curves, labor exposure, insurance, compliance, capital intensity, and supply chain topology. When inputs change, downstream systems reorganize whether anyone agrees or not.

That is where leverage lives.

Change Happens in Lanes, Not All at Once

No economy flips overnight.

Hemp and bamboo are lanes, not the entire economy. Their impact is outsized because they sit upstream across textiles, construction, composites, packaging, energy systems, and the material envelopes that support advanced manufacturing.

Partial substitution is enough. Systems do not require total replacement to bend.

Hemp and Bamboo Are Already Industrial Materials

These materials are not symbolic.

Hemp and bamboo are already used in fibers and structural materials, reinforced plastics and composites, bio based carbons and graphites, binders and hybrid chemistries, building systems, packaging, filtration, and remediation. Adoption is uneven, which is exactly what every industrial transition looks like at this stage.

No Sector Is Isolated

Even advanced industries like semiconductors do not exist in a vacuum.

Chips sit inside systems built on carbons, silicates, resins, housings, thermal interfaces, packaging, and logistics. Changing the material envelope around those systems changes cost, toxicity, risk, and resilience without pretending core technologies disappear.

The Landed Cost Math Has Reset

Global manufacturing still optimizes for landed cost, but the baseline is no longer what it was.

Transportation, door to door logistics, port congestion, insurance, inventory dwell time, and working capital drag are structurally higher. Labor, energy, compliance, and financing costs abroad have risen materially.

This is not volatility. It is a new equilibrium.

At scale, domestic inputs are increasingly competitive dollar for dollar even before risk is priced in. Procurement teams already know this.

Scale Requires Standards

Nothing scales without standardization.

Materials must be specified, graded, and traceable before they can be insured, underwritten, written into bills of materials, and contracted at volume. This is where decisions move from opinion to spreadsheets.

CAPEX Is Solved Through Sequencing

Industrial transitions fail when capital is treated as all or nothing.

Successful systems scale incrementally through modular facilities, rural processing, shared infrastructure, and public private incentives. Capacity is built just far enough to prove reliability and bankability.

You do not rebuild everything. You validate the next step.

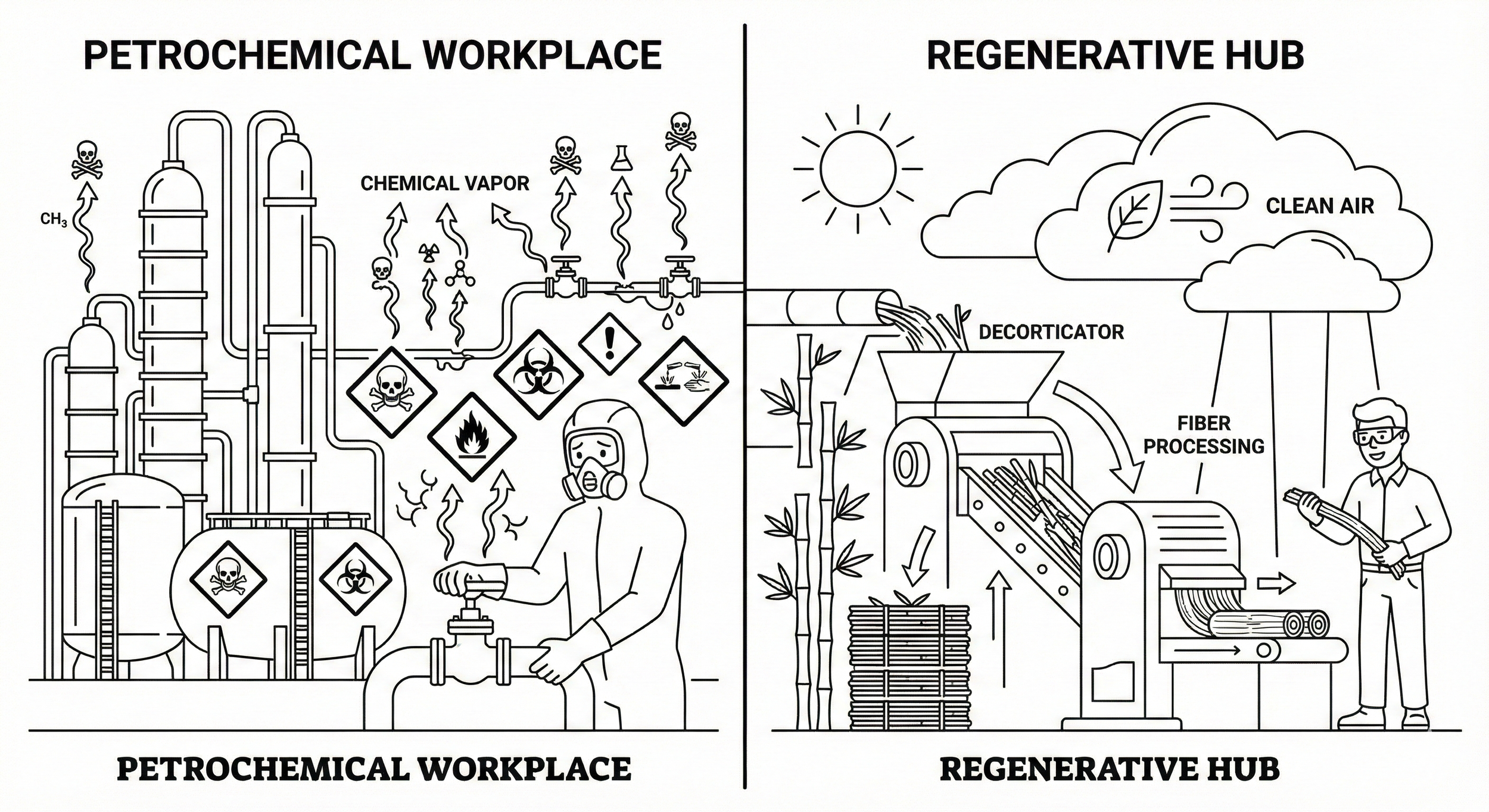

Lower Toxicity Improves the Factory Floor

Material toxicity shows up directly in operations.

Lower toxicity systems reduce OSHA recordables, workers comp claims, health costs, PPE burden, absenteeism, and turnover. Productivity improves. Insurance economics improve. These effects show up on plant P and Ls, not marketing decks.

Production Is Being Democratized

Standardized materials combined with additive manufacturing change who gets to produce.

Six figure molds stop being the entry gate. Iteration accelerates. Production decentralizes. Supply chains shorten. Manufacturing moves closer to demand. Centralized manufacturing remains, but participation widens and resilience improves.

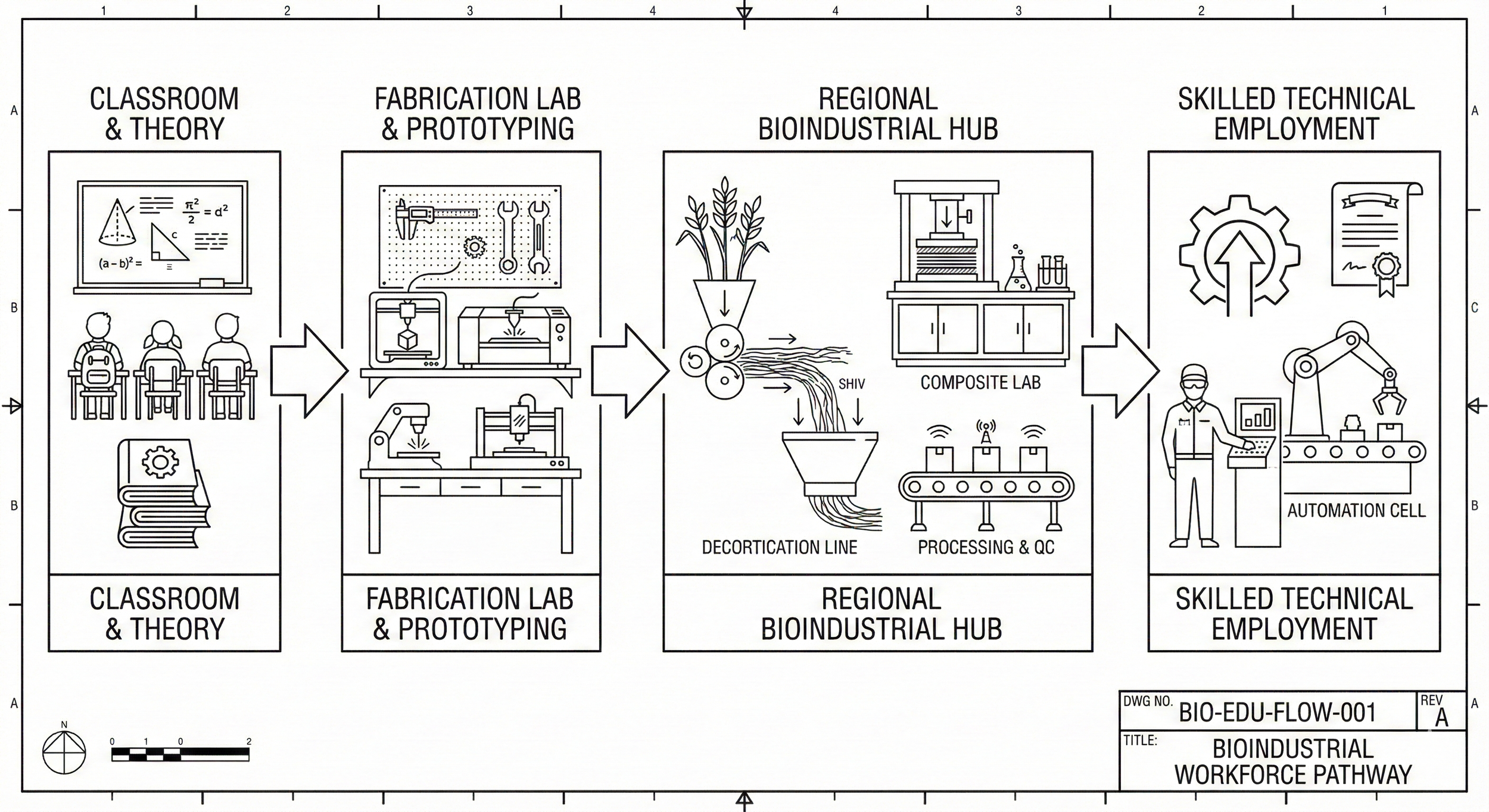

Workforce Development Follows a Proven Human Pattern

This mirrors how economies develop globally.

Regions move from crafts to textiles to finishing to manufacturing as skills and secondary education grow, often guided by experienced industry operators. Workforce development and industrial scale grow together, not sequentially.

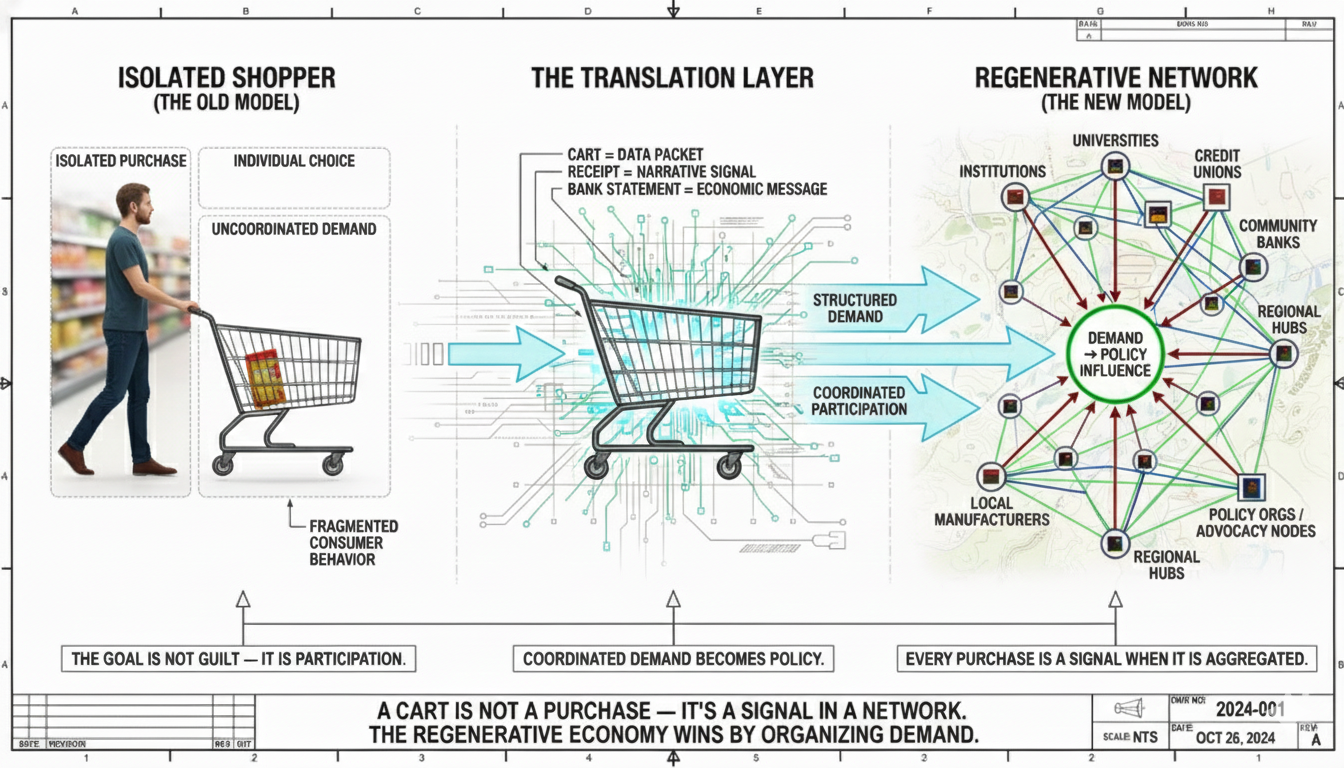

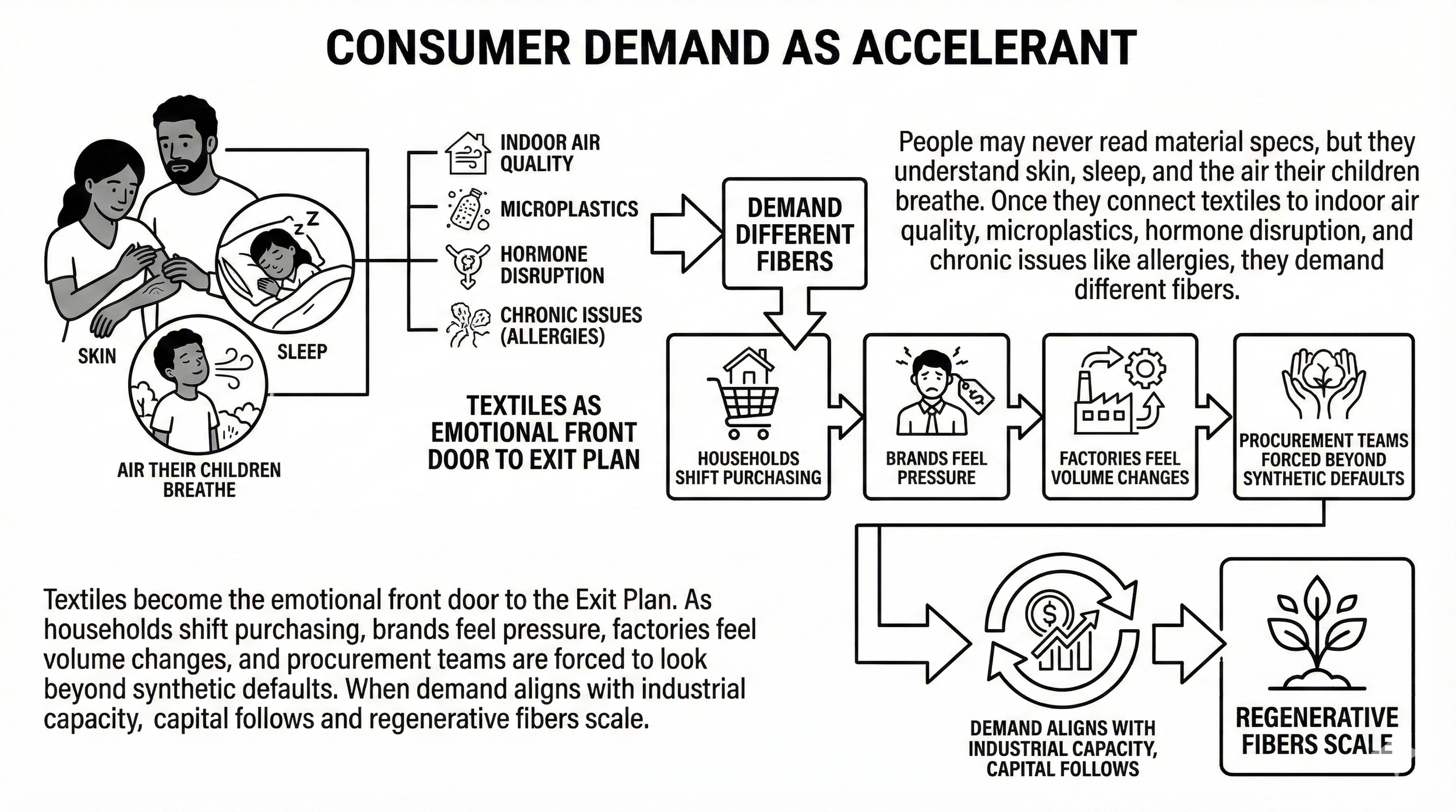

Consumer Demand Stabilizes the Transition

Consumer demand is not the foundation. It is the stabilizer.

Cause based purchasing provides early offtake signals that keep systems viable while scale and process maturity catch up. Support comes from lived economic and health benefits, not ideology.

Once Alternatives Exist, Competition Reprices

When viable alternatives are in place, competition changes permanently.

Insurance premiums rise for legacy systems. Liability becomes actionable. Courts and regulators ask different questions. Capital adjusts risk assumptions.

This is cost internalization. When harm is no longer unavoidable, it becomes expensive.

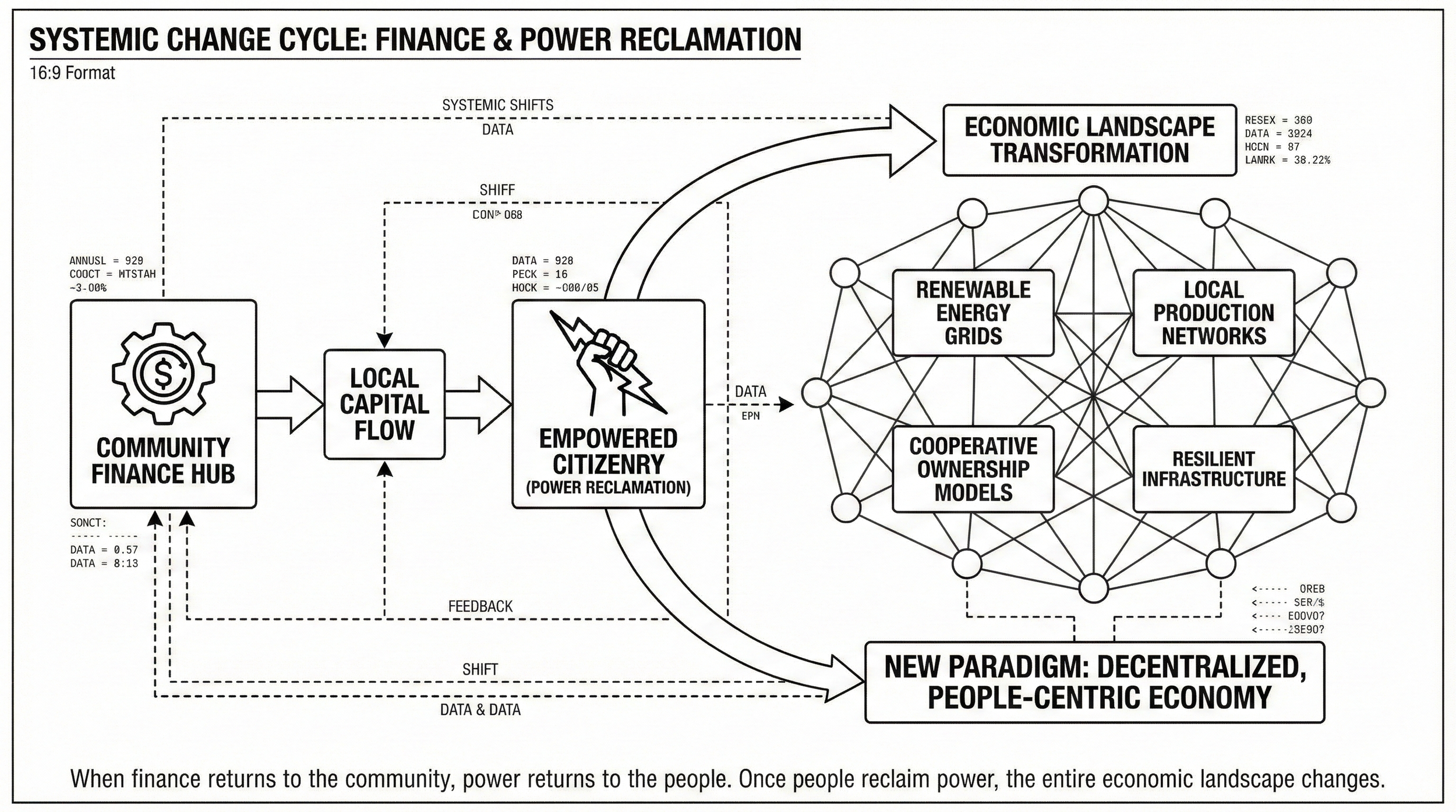

Money Flow Reshapes Politics

Political influence follows revenue.

As margins compress in legacy systems and grow in alternatives, campaign funding shifts. Incentives and subsidies follow risk adjusted return, not rhetoric. Consumer spending moves faster than elections. Capital moves faster than legislation.

Policy follows both.

A Bioeconomy Is a Carbon and Risk Strategy

Carbon capture starts in fields, not factories.

Hemp and bamboo rapidly capture carbon through biomass growth and soil regeneration, then lock that carbon into durable goods like buildings, composites, and infrastructure. Carbon shifts from future liability to present asset embedded in the economy.

Climate disasters are no longer edge cases. They are recurring line items.

Floods, fires, heat events, and infrastructure failure drive insurance retreat, municipal insolvency, emergency spending, and healthcare strain. Regenerative land use and distributed production reduce exposure. When risk drops, insurance returns. When insurance returns, capital follows.

AI Collapses the Timeline

Fossil fuel systems took a century to mature because learning was slow and sequential.

AI collapses industrial learning curves by allowing materials discovery, process optimization, workforce training, and capital deployment to happen in parallel. What once took generations can now be achieved an order of magnitude faster.

This Is Already Happening Globally

This is not speculative.

The EU, China, and India are already investing in domestic materials, regional processing, circular manufacturing, workforce pipelines, and AI accelerated industrial learning. We are not early. We are late.

Being late is not fatal. It means the lessons are visible and the mistakes are known.

Material Shifts Rewire Geopolitics

Geopolitics follows material dependence.

As bio based inputs grow, manufacturing gravity diversifies away from East Asia, supply chains extend into Latin America, African regions gain leverage through biomass and processing, and long standing petrochemical dependencies weaken over time.

This does not end global trade. It redistributes power.

The Outcome

The goal is not to replace all manufacturing.

The goal is influence over inputs, production topology, workforce safety, risk, capital allocation, money flow, and power.

That is how economies actually bend.

Read the Full Framework

If you want the deeper context, material pathways, and real world examples behind this doctrine, I laid them out in my book Evolution Mine: Genesis.

It is free by design. This is about concept dissemination, not cash.

You can read it here:

https://www.nowweevolve.com/view-the-book