Climate by the Numbers: Hemp & Bamboo Can Bend the Curve

Blueprints for the Next Economy

Bamboo & Hemp. What we use repairs the planet as a bonus.

You don’t have to chain yourself to a smokestack to pull carbon from the sky.

You can do it with floorboards, car door panels, lunch trays—if the feedstock is right and the water keeps flowing.

The Carbon Goal

To keep global warming within 1.5 °C, humanity must remove or avoid billions of tons of CO₂ each year.

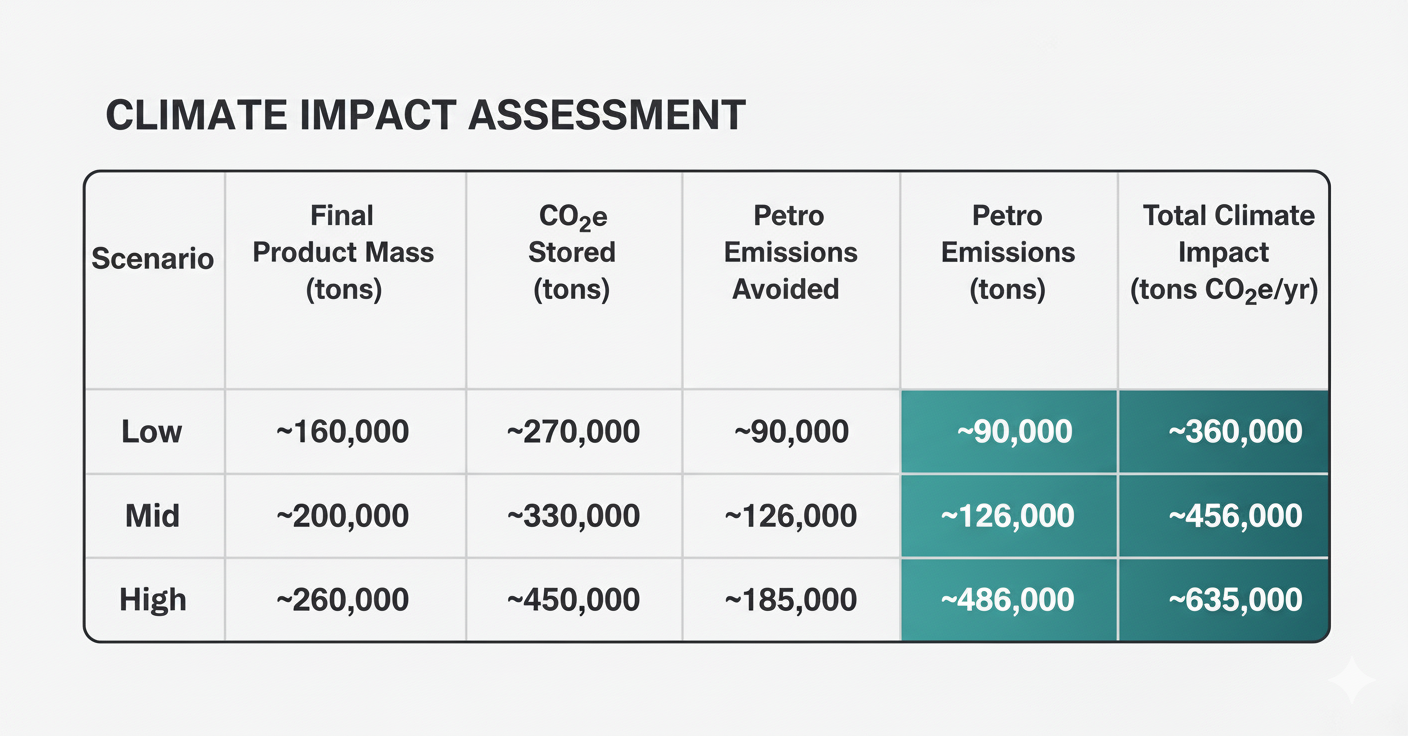

That sounds abstract until you shrink it to a single region: 50,000 acres of hemp and bamboo, supplied by two midsize composite mills.

Using conservative yield data and standard carbon accounting, a pilot of that size can lock away or avoid nearly half a million tons of CO₂e every year, the annual emissions of roughly 100,000 U.S. cars.

Climate impact

How Ordinary Buying Keeps the Mills Hot

These tons don’t require heroic consumer sacrifice.

The output of a 50,000-acre pilot can be absorbed almost invisibly:

Construction: If one mid-size metro replaces 5 % of new wall panels with hemp/bamboo composites, that alone consumes most of the construction-grade material.

Mobility: A single major EV maker specifying plant-fiber interior panels would take a third of the mobility output.

Consumer goods: Two national retailers switching small-appliance housings from plastic to molded fiber would soak up the rest.

The climate impact happens behind the scenes.

Shoppers buy a lunch tray or a shampoo bottle; carbon quietly stays out of the sky.

Water: The Hidden Enabler

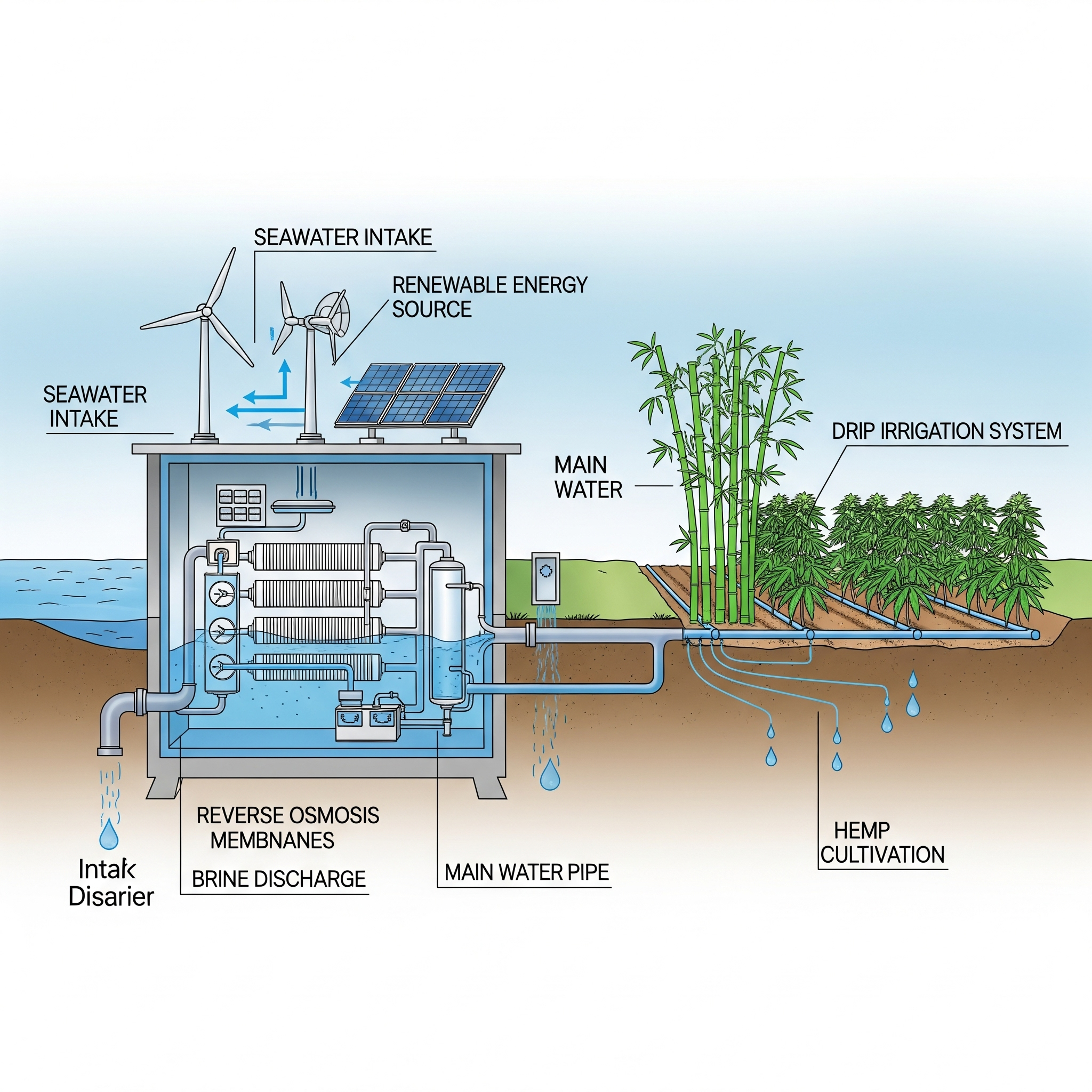

Critics often ask whether we can scale bio-materials without draining freshwater.

The answer is yes—if we pair acreage growth with desalination and advanced water recycling.

Coastal Desal Hubs: Modern reverse-osmosis plants powered by offshore wind or solar can deliver irrigation water with near-zero net emissions.

Wastewater Reuse: Municipal and industrial greywater can be polished to agricultural grade, reducing draw on rivers and aquifers.

Closed-loop irrigation: Drip and sub-surface systems cut losses by up to 70%, making every gallon count.

With renewable-powered desal and high-efficiency irrigation, arid coastal zones become new bio-fiber frontiers.

A thousand acres of bamboo watered by a single mid-scale desal plant can sequester more carbon each year than the plant emits to run itself.

Why Hemp and Bamboo Work

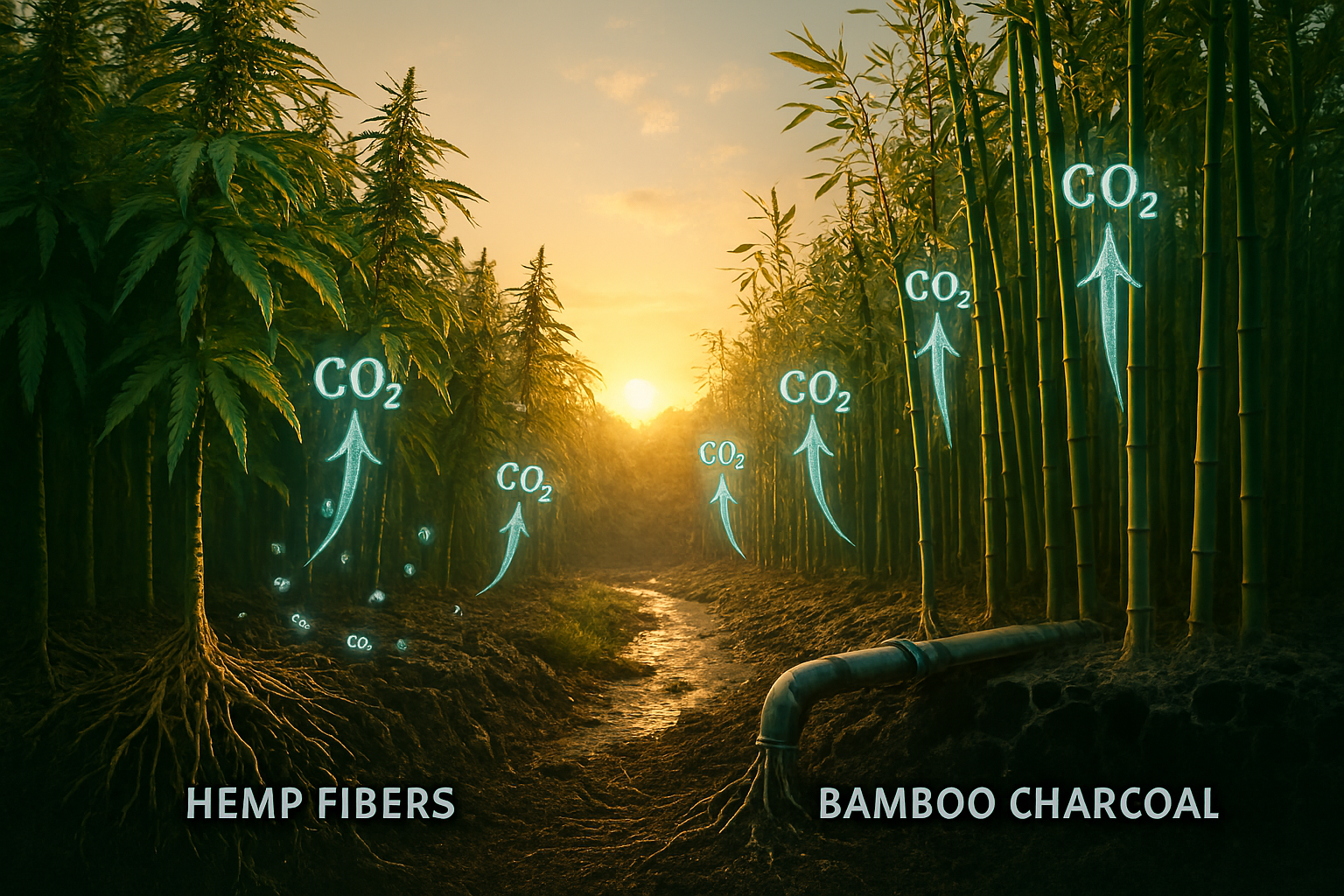

Durable Carbon Storage – Products last decades, keeping biogenic carbon out of the atmosphere.

Material Substitution: Every plant-fiber panel or housing displaces petro-plastics or high-carbon steel.

Job Creation: Two midsize mills processing this feedstock would employ hundreds and anchor a regional supply chain.

The Blueprint for Scale

Acreage – Replicate the 50k-acre pilot across five coastal regions and you approach 2.5 million tons of CO₂e per year in combined impact.

Mills & Markets: Each regional cluster: two composite mills, predictable municipal and OEM buyers.

Procurement Standards: Governments and large retailers specify “documented carbon-negative composites,” creating bankable demand.

Your Role—Invisible but Powerful

Whether you’re a builder, a municipal buyer, or a family stocking a pantry, your purchase order is a carbon lever.

The climate math is already done; all that remains is to aim our routine spending at the right materials.

Protests change headlines. Purchases change factories.

Half a million tons of CO₂e can disappear every year—quietly—because ordinary products are made from hemp and bamboo.

Read the full story in the book.

Evolution Mine: The Industrial Evolution—the blueprint for breaking the petrochemical playbook and building a regenerative economy.

👉 Buy on Amazon